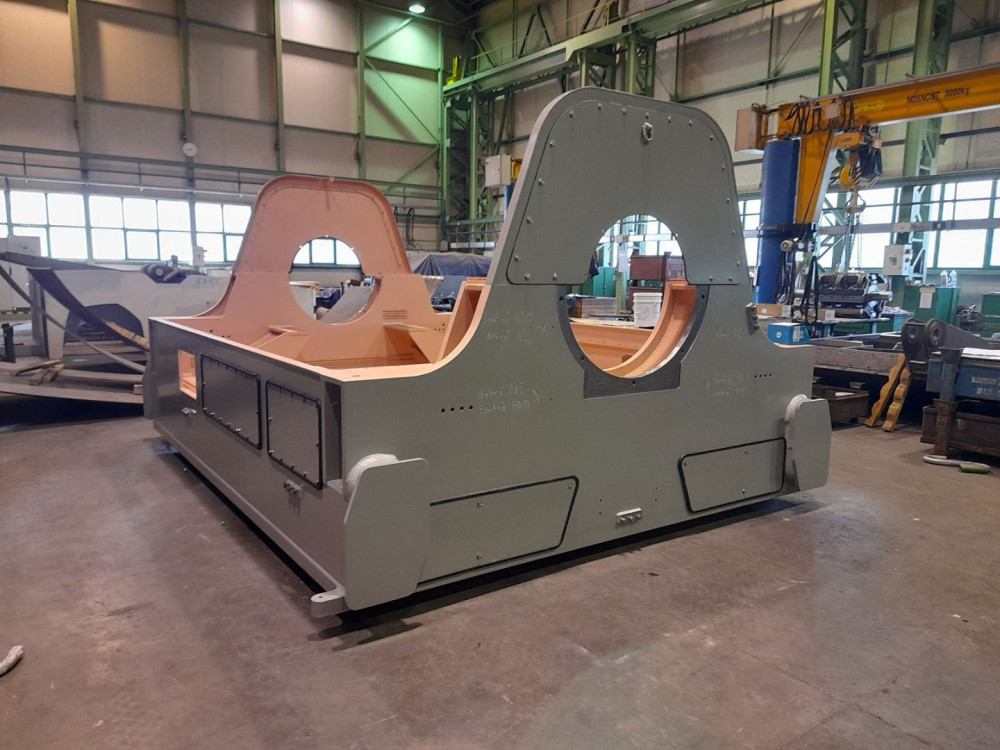

Precision welding for demanding projects

Since its founding, OSTROJ has focused on manufacturing machinery and components for the most challenging industrial sectors. Over the years, we have contributed to numerous complex projects—from extreme-condition mining and demolition equipment to the energy sector.

Our services go beyond welding and manufacturing medium and heavy structures up to 50 tons. We also provide optimal production process design, surface treatments, precision machining, and final assembly. By combining automated processes with the expertise of our skilled welders, we ensure exceptional quality and durability. We work with high-strength steel materials, including S355, S690, and S960, with all welding processes overseen by certified IWE/EWE welding supervision.